Streamline Your WMS Start-Up (Pt. 1)

March 24, 2014 By: Senior Management | Topics: IT SolutionsDespite their importance, successful implementations of warehouse management systems (WMS) are seldom fully realized in highly automated distribution centers. Today, simply installing material handling equipment is not enough. A more holistic perspective is required for starting up successfully operating distribution centers.

Supply chain expert Jeff Graves discusses how delays in warehouse management system start-ups can be avoided with realistic planning and careful management before go-live. Topics covered in this four-part series:

- Warehouse Management System Goals

- Risks Affecting WMS Implementation

- Planning is Key

- Implementation Insurance

PART 1: Warehouse Management System Goals

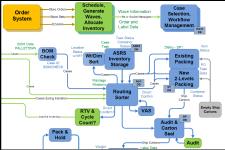

The objective of the WMS is to provide a set of computerized procedures to manage the movement of inventory and orders within the warehouse, and enable a seamless link to order processing, logistics management and material handling equipment (MHE) systems within the facility. These MHE systems handle receiving, put-a-way, storage, picking, packing, labeling, sortation, shipping and returns. External to the warehouse, the WMS links to freight carriers for incoming deliveries and outgoing order delivery confirmation.

Highly automated distribution centers may have many material handling equipment components and sub-systems, each with their own discrete control systems such as warehouse control systems (WCS) and programmable logic controllers (PLCs), which require integration with the warehouse management system into a single-source point of control.

Additionally, WCS, traditionally functioning as middleware real-time interfaces between the WMS and PLCs that control the material handling equipment, are now taking on more functionality and looking more like a WMS, effectively blurring the lines between conventional WCS and WMS applications. Such WMS functions like managing order activity and batching orders for waving can now be accessed through a WCS, allowing distribution executives another option to fine-tune their DCs while optimizing their investment in software.

Depending on the degree of MHE automation in use within the warehouse, an arsenal of automatic identification and data capture (AIDC) technology can be employed, such as barcode scanners, mobile computers, wireless LANs, magnetic stripes, optical character recognition (OCR) and radio-frequency identification (RFID) to efficiently monitor the flow of goods. These units capture and relay data throughout the distribution system in real-time via wireless transmission to the WMS, which then can make available comprehensive and detailed reports about the status of inventory and orders moving through the warehouse.

WMSs process huge volumes of data on a split-second, real-time basis with near flawless accuracy, while integrating with ERP, shippers, hundreds of AIDC units, and dozens of MHE systems operating thousands of I/O.

Clearly, the WMS is the most critical component of a warehouse’s operation. Our next post will identify the risks affecting WMS implementation.

Sedlak has been providing innovative distribution and fulfillment solutions to retailers, manufacturers, wholesalers and third-party logistics providers for over 55 years. Selection and implementation of warehouse management systems is one of our lead services offerings.

We hope that you will find the insights contained in this series helpful to your business. If there is any way we can be of assistance with your distribution or facility design needs, please feel free to contact us by filling out the form below.