Transform Your Network into an Agile Supply Chain

March 25, 2020 By: Senior Management | Topics: 3PL, Automation & Robotics, IT Solutions, Network Strategy, Productivity & Labor, Supply ChainThe modern supply chain has never experienced a crisis quite like the COVID-19 pandemic. It’s rare to see countrywide company shutdowns. For your business to respond quickly and effectively, there are things you must do NOW to optimize your network into an agile supply chain. There is also data you need to warehouse for future business continuity. Fortunately, you can take action using the resources you already have.

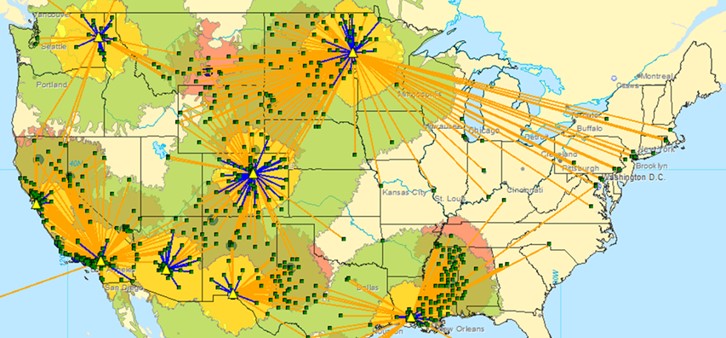

Pictured below: an example distribution network.

Optimize Your Network

Optimize Your Network

Something Amazon is especially good at is network optimization: this includes the proper placement of distribution centers, product and safety stock; utilizing 3PLs where appropriate; repurposing portions of or entire manufacturing facilities for distribution; and leveraging pop-up warehouses to account for increased demand. Proximity to customers, labor costs, transportation costs, etc. are all factored in.

COVID-19 is impacting international distribution networks and hitting home at a very local/final mile level. Conducting a network optimization NOW will allow for greater supply agility and should be done immediately when you encounter a wave of unexpected change such as COVID-19.

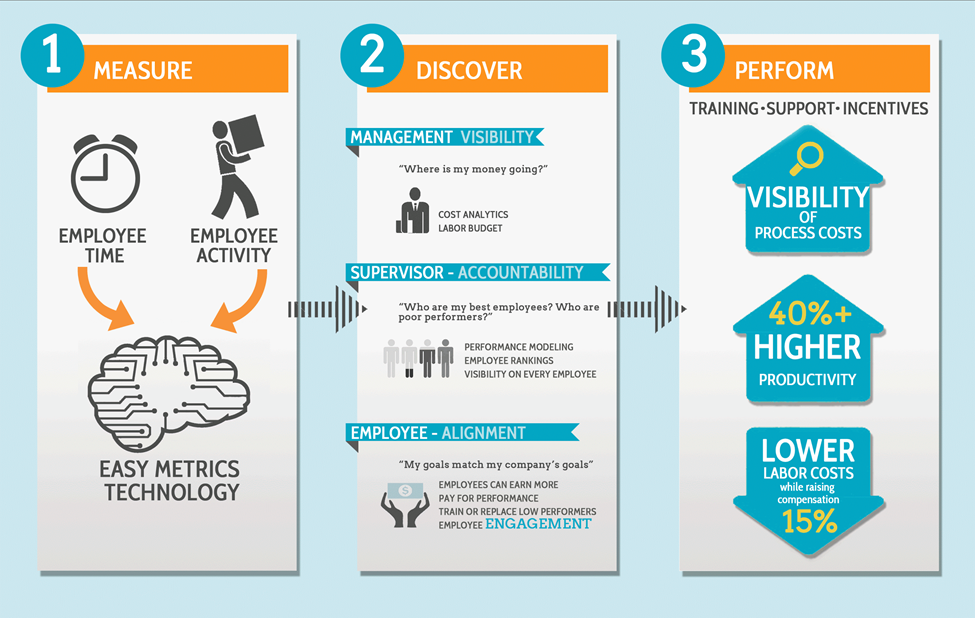

Leverage your Labor Management Software (LMS)

Supply is not dwindling yet and demand is increasing. However, quarantining/shelter-in-place is having a huge impact on the labor market. This is reducing the amount of trained employees that can expedite orders to keep up with the demand. It is essential to allocate your labor force for the tasks required to get you through these challenges. Your LMS will arm you with the data you need to make those decisions. Below is an example of the Easy Metrics LMS and how the data it collects can help your supply chain performance.

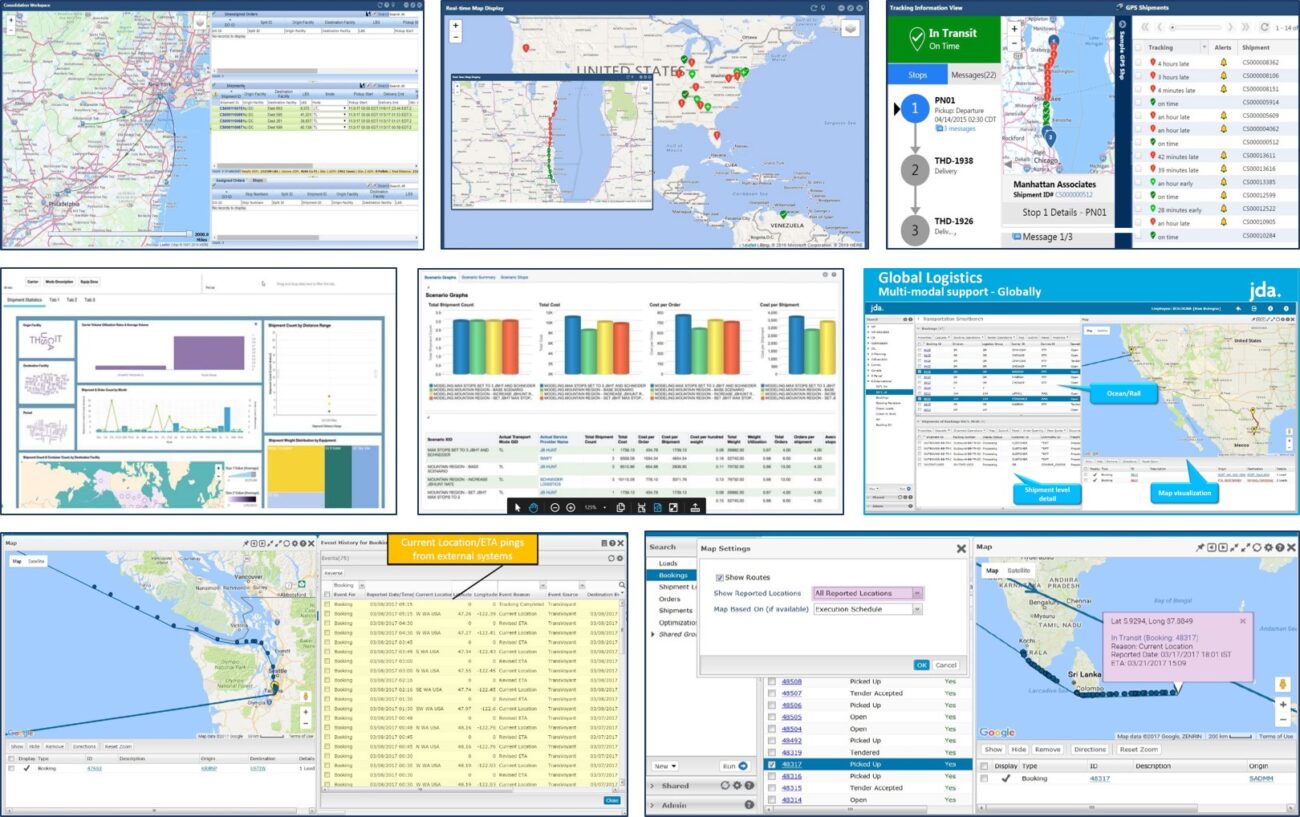

Capitalize on Your Supply Chain Execution (SCE) Software

Quick and decisive actions are required in this pandemic environment. Real-time data is the new norm, so tap into the Supply Chain Execution (SCE) software you own or that your 3PL provides. This is crucial for planning, executing, delivering for the final mile and routing all your global and domestic shipments (see the example below for scenario planning). It allows you to manage your supply chain by exception. Your control tower mapping tools will allow for dynamic and predictive analytics. It will show delays and congestion, factor in weather and automatically reroute shipments. (Pictured below: examples of transportation execution software.)

While there are tasks you need to execute immediately to keep your supply chain in motion, there’s also data you must capture now for future supply chain continuity. This can be used to create a guide for handling catastrophic disruptions in your supply chain such as COVID-19.

While there are tasks you need to execute immediately to keep your supply chain in motion, there’s also data you must capture now for future supply chain continuity. This can be used to create a guide for handling catastrophic disruptions in your supply chain such as COVID-19.

For example, we worked with our longtime client Ascena Retail Group Inc. to develop a pre-established game plan. This network-focused business continuity plan (BCP) strategy is designed to minimize service impact in the event a major portion of or entire facility goes off-line for a significant period of time.

To accomplish these objectives, Sedlak selected different scenarios and conducted an analysis to develop recommendations. Ultimately Sedlak created a plan to restore order fulfillment to 80% capacity within 30 days of an unplanned catastrophic disruption. A “playbook” was delivered to Ascena that included a decision tree, schedule of tasks and communication plan.

Implement Practical Levels of Automation in your Distribution Processes

In an effort to combat today’s labor shortage and capitalize on technology, you may have an opportunity to justify an investment in automation. To do so, you must be consistently measuring your data. The assistance of data-driven consulting can bring a practical level of automation to your distribution intensive environments.

Start by establishing a baseline for your standard cycle times vs. these new peaks you observe to properly plan inventory and safety stock. This measurement should start from June 2019 to six (6) months after the crisis has abated and business has stabilized. This data will be required for the creation of an internal BCP when disaster strikes.

If you do not have an agile supply chain, it will inevitably break. Schedule time to speak with a Sedlak team member to learn more about the steps to take NOW to re-optimize your supply chain. Email us at info@jasedlak.com or give us a call at 216-206-4700.