Managing Healthcare Logistics Spend – A Vital Corporate Function

October 21, 2016 Topics: HealthcareFor the healthcare industry, the delivery of products – from manufacturers to distributors to providers to patients – is often an isolated entity in the supply chain. Often, efforts to optimize healthcare delivery are unwittingly made at the expense of other supply chain components, and vice versa. Inventory and the number of facilities are the classic trade-offs. A medical device company, for example, could opt to deploy multiple facilities to reduce shipping distances to its customers; however, it will incur higher fixed costs for those additional assets and higher inventory costs to keep product available at numerous locations. Conversely, the company could run all of its distribution from a single facility, which would provide the lowest fixed facility costs and the lowest inventory costs, but it would undermine those savings with higher costs due to longer travel distances and more expensive modes of transportation to achieve targeted customer service levels.

The simple fact is that a healthcare organization or life sciences company can’t address any aspect of its supply chain in a vacuum. Rather, it must maintain a careful balance so that it doesn’t end up sub-optimizing the whole. Striking that balance requires companies to more proactively and holistically manage their logistics function.

Not surprisingly, logistics management simply isn’t, and never has been, a core competency for many companies in the healthcare industry. These companies often began life as entrepreneurial ventures dedicated to developing, manufacturing, marketing and selling life-saving/life-enhancing ideas and products, and doing so as creatively and quickly as possible. Moving goods from one place to another always took a back seat, as these companies relied on the carrier community to “get my stuff where it needs to be.” Exacerbating the problem is the fact that some companies just don’t have the resources to commit to managing logistics internally, so they rely on their vendors or customers to direct freight movement.

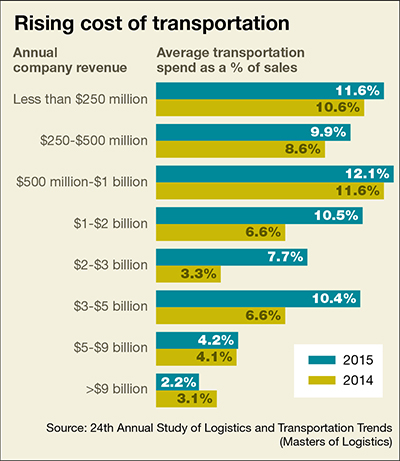

The trouble is, transportation of healthcare products is not an insignificant function. To the contrary, if it’s not well managed, shipping can erode an organization’s profitability and overall business performance. Take costs, for example. According to one study, the average transportation spend as a percentage of sales for many companies across industries has skyrocketed. According to one study, between 2014 and 2015 it jumped from 6.6 percent to 10.5 percent for $1 billion to $2 billion companies; 3.3 percent to 7.7 percent for $2 billion to $3 billion organizations; and 6.6 percent to 10.4 percent for $3 billion to $5 billion enterprises. For biopharma in particular, Pharmaceutical Commerce reports that managing the transportation of temperature-controlled products (refrigerated and frozen) will total $12.6 billion in 2016, continuing an 8 percent to 9 percent per year growth rate. Those increased costs have a direct impact on margins and make companies less competitive.

The trouble is, transportation of healthcare products is not an insignificant function. To the contrary, if it’s not well managed, shipping can erode an organization’s profitability and overall business performance. Take costs, for example. According to one study, the average transportation spend as a percentage of sales for many companies across industries has skyrocketed. According to one study, between 2014 and 2015 it jumped from 6.6 percent to 10.5 percent for $1 billion to $2 billion companies; 3.3 percent to 7.7 percent for $2 billion to $3 billion organizations; and 6.6 percent to 10.4 percent for $3 billion to $5 billion enterprises. For biopharma in particular, Pharmaceutical Commerce reports that managing the transportation of temperature-controlled products (refrigerated and frozen) will total $12.6 billion in 2016, continuing an 8 percent to 9 percent per year growth rate. Those increased costs have a direct impact on margins and make companies less competitive.

Add to this pressure the idea that technologies in the healthcare space are ever increasing patient demand for “anytime, anywhere” healthcare services. With cost and service pressures intensifying for most healthcare companies today, managing transportation in a more formal, holistic and sophisticated way should be a priority. Organizations that ignore this element of the supply chain and the impact it can have on the business run the risk of doing everything else right and still not meeting their business objectives. Although it’s essential for healthcare and life sciences companies to pay attention to logistics as an integrated part of the supply chain, it is rarely viewed or managed as the critical function it is.

A rule of thumb in transportation is to plan centrally for scale, and execute locally to fulfill unique requirements. A healthcare organization, for example, needs a central view of all of its healthcare logistics – suppliers, hospitals, provider offices, home health care, patients, shipments, carriers, and contracts – to be able to aggregate shipments, select the most cost-effective modes, and negotiate contracts around volumes. Then various operating entities can execute on a daily basis by aggregating, dispatching, and processing activities. One operating unit might see higher costs, but another may achieve significantly lower costs, and that can be an acceptable outcome. The ultimate goal is to manage logistics in a way that most benefits the organization overall through the optimal balance between cost savings and, ultimately, better patient care.

In one instance, Apria Healthcare, a home healthcare products provider that serves 2.4 million patients annually, partnered with a logistics provider to identify distribution cost savings and redesign its transportation model to optimize shipping rates and reduce expedited freight spend. Moving to a greater percentage of full truckload shipments and improving backhaul utilization helped Apria to realize significant transportation cost savings.

Taking a holistic view requires healthcare and life sciences companies to ask a number of key questions: Who is managing the product transportation (inbound, inter-facility, and outbound) process and how? Is our network structured to meet “best service/least cost” objectives? Do we have a system to track and audit every detail of every freight movement? How about the auditing and freight bill processing systems? Which shipment quantities are most economical? Are we a good customer to our carriers? What is our carrier strategy – cheap and mediocre service; expensive and top quality; or the best combination of each dynamically selected for each shipment? The answers to those questions begin to get at the essence of true logistics management.

It’s not sexy and doesn’t grab headlines. But the payoffs can be significant in terms of cost reduction, better customer service, and improved patient care. And for those in the healthcare industry feeling the pressure to enhance both aspects of their business, optimizing logistics is an operational necessity.

Dennis Heppner has 20+ years of experience in transportation, logistics and supply chain operations, consulting and third party providers. Sedlak is an industry leader in supply chain strategy and distribution, with a specialized practice in healthcare. Our solutions help optimize supply chain operations, balance cost/service trade-offs, and pursue intelligent growth strategies.

If there is any way we can support your healthcare supply chain or distribution optimization, please feel free to contact us by filling out the form below.